Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

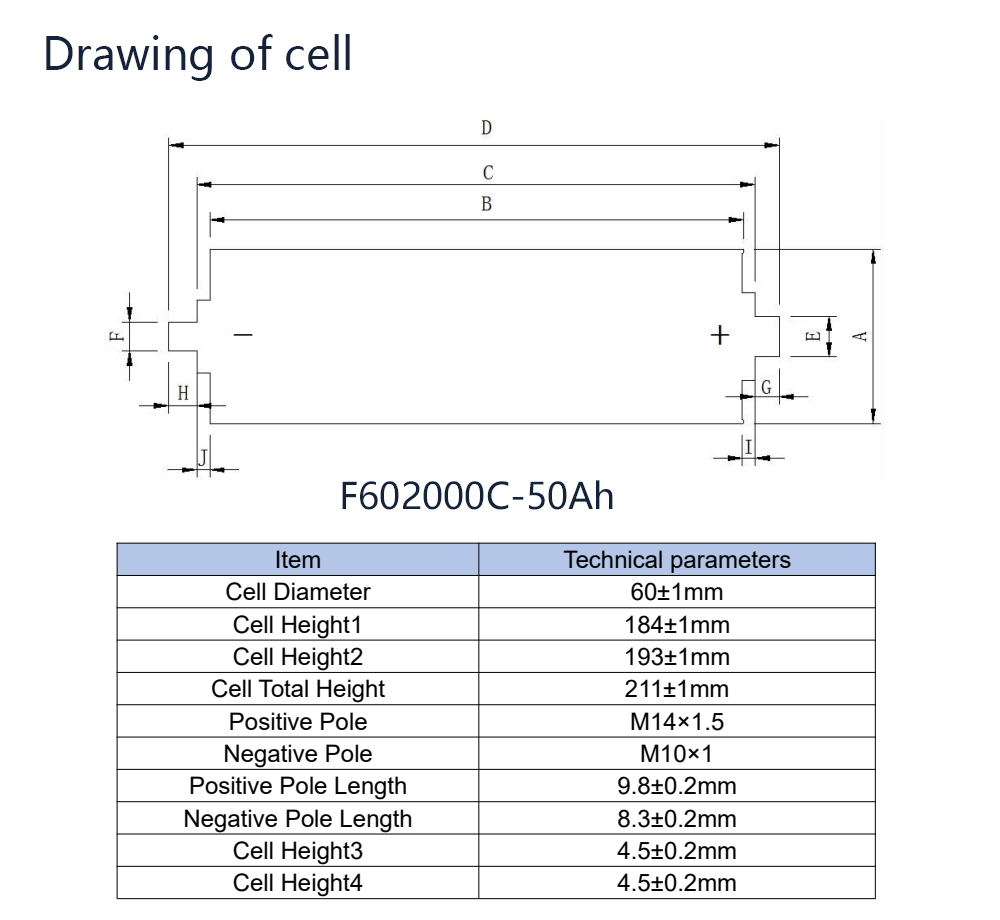

Model No: F602000C-50Ah 60 Series

Jenis pembayaran: L/C,T/T,Paypal

Baterai Lithium-ion Silinder F602000C-50Ah Seri 60 LFP

untuk baterai cadangan stasiun pangkalan

Kinerja Dasar

|

No. |

Item |

Specification |

|

1 |

Nominal Capacity |

50Ah ,0.5 C discharging(25±2℃) |

|

2 |

Nominal Voltage |

3.2V |

|

3 |

Charge Ending Voltage |

3.65V |

|

4 |

Discharge Ending Voltage |

2.5V(≥0℃) 2.0V(< 0℃) |

|

5 |

Standard Charging Method |

25±2℃ 0.5C constant current charge to 3.65V, then constant voltage 3.65V charge till charged current declines to ≤ 0.05C |

|

6 |

Standard Discharging Method |

25±2℃ 0.5C constant current discharge to 2.5V |

|

7 |

Max.Pulse Charging Current |

2C (15℃~45℃, 50%SOC) ≤30S |

|

8 |

Max.Pulse Discharging Current |

3C (15℃~45℃, 50%SOC) ≤30S |

|

9 |

Operating environment |

Charging: -0℃-55℃, max.90%RH Discharging: -20℃-55℃, max.90%RH |

|

10 |

Impedance |

<0.7mΩ |

|

11 |

Cell Weight |

1.10kg±0.20kg

|

|

12 |

Mass Energy Density |

145Wh/Kg

|

|

13 |

Volume Energy Density |

308Wh/L

|

Karakteristik listrik

|

NO. |

Item |

Criterion |

Test Method |

|

1 |

0.5C discharging capacity |

Discharging capacity is not less than normal capacity. |

After Standard Charging, rest 5 minutes ,then 0.5C discharge to ending voltage. |

|

2 |

Room temperature 1C discharging capacity(initial capacity) |

Discharging capacity must be not less than nominal capacity and no more than 110% nominal capacity. Range:≤5% the average of initial capacity |

After the cell is charged with 1C,and then discharge it to 2.5V with 1C.Repeat 5 times(If the range of capacity is no more than 3% nominal capacity and sustains 3 times,stop the test early),average the last three. |

|

4 |

Standard cycle life |

Discharging capacity is not less than 80% initial capacity when have cycled 2000 times |

Test condition: 25±2℃ Charge:1C to 3.65V, then constant voltage 3.65V charge till charged current declines to ≤ 0D.i0s5cCharge:1C to 2.5V When the discharge capacity reduced to 80% of rated capacity, Stop testing |

|

5 |

Ratio discharging capacity |

Discharging capacity should be not less than 90% initial capacity |

After the cell is charged with 1C,and then discharge it to 2.5V with 3C.Compare with the initial capacity. |

|

6 |

Ratio charging performance |

Discharging capacity should be not less than 80% initial capacity |

After the cell is charged with 2C,and then discharge it to 2.5V with 1C。Compare with the initial capacity. |

|

7 |

Low temperature discharging capacity |

Discharging capacity should be not less than 70% initial capacity |

After the cell is charged with 1C,keep the cell at -20℃±2℃ for 24 hours,and then discharge it to 2.0V with 1C at -20℃±2℃。Compare with the initial capacity. |

|

8 |

High temperature discharging capacity |

Discharging capacity should be not less than 90% initial capacity |

After the cell is charged with 1C,keep the cell at 55℃±2℃ for 5 hours,and then discharge it to 2.5V with 1C at 55℃±2℃。Compare with the initial capacity. |

|

9 |

Charge retention capacity and recovering capacity of room temperature |

Charge retention capacity should be not less than 85% initial capacity ; recovering capacity should be not less than 90% initial capacity |

After the cell is charged with 1C,keep the cell at room temperature for 28days , and then discharge it to 2.5V with 1C at room temperature. Metering the charge retention capacity;Then the battery should be charged with 1C and should be discharged with 1C at room temperature. Metering the recovering capacity. |

|

10 |

Charge retention capacity and recovering capacity of high temperature |

Charge retention capacity should be not less than 85% initial capacity ; recovering capacity should be not less than 90% initial capacity |

After the cell is charged with 1C,keep the cell at 55℃±2℃ for 7daysand rest 5h at room temperature,discharge it to 2.5V with 1C at room temperature. Metering the charge retention capacity ; Then the cell should be charged with 1C and should be discharged to 2.5V with 1C at room temperature. Metering the recovering capacity. |

|

11 |

Appearance |

The surface of cell should be dry and labeled clearly,and without burr , scratch , contamination,distortion, break and so on |

Visual inspection |

|

12 |

Polarity

|

The cell polarity should be labeled clearly and correctly |

Measured with voltmeter |

|

13 |

Dimension and Weight |

The cell dimension and weight accord with stated value |

Using measuring tools and electronic scale |

|

14 |

Storage |

Discharging capacity should be not less than 90% initial capacity |

After the cell is charged with 1C,and then discharge it with 1C in 30min at room temperature. Keep the cell at 45℃±2℃for 28days and rest 5h at room temperature. Then the cell should be charged with 1C and should be discharged to 2.5V with 1C at room temperature. Metering the discharging capacity. |

Karakteristik Lingkungan

|

NO |

Item |

Criterion |

Test Method |

|

1 |

Constant temperature and constant humidity test |

No explosion,no fire, no leakage. Discharging capacity is not less than 85% initial capacity |

After Standard Charging, test condition: Temperature:40±5℃ Relative Humidity:90~95%RH Storage Time:48 hours Then return to room temperature for 2 hours, Then 0.5C discharged to ending voltage. |

|

2 |

Vibration test |

No explosion, no fire,no Leakage |

After Standard Charging , fixed the cell to vibration table, then subjected to vibration testfor 30 minutes per axis of XYZ axes. Frequency rate:1oct/min Vibration frequency:10Hz-30Hz Excursion (single amplitude):0.38mm Vibration frequency:30Hz-55Hz Excursion (single amplitude):0.19mm |

|

3 |

Shock test |

No explosion, no fire,no leakage |

After Standard Charging,test condition: Acceleration:100m/s2 Pulse lasting time:<16ms Shock times:1000±10 times |

Karakteristik Keamanan

|

1 |

Overcharge test |

No explosion,no fire |

After the cell is charged with 1C , test condition: Charge : 1C to 5.475V When the voltage get to 5.475V or charge for 60 min ,Stop testing and observe 1h. |

|

2 |

Over-discharge test |

No explosion,no fire,no leakage |

After the cell is charged with 1C,discharge 90 min at 1C,stop testing and observe 1 h. |

|

3 |

Short-circuit test |

No explosion, no fire |

After the cell is charged with 1C,Short circuit the positive and negative 10 min,and the resistance of the external line is not more than 5mΩ,Stop testing and observe 1h. |

|

4 |

Free fall test |

No explosion,no fire,no leakage |

After the cell is charged with 1C,the positive and negative terminal face down,and then cell falls freely from the height of 1.5m down to the cement floor,and observe 1h. |

|

5 |

Heating test |

No explosion, no fire

|

After the cell is charged with 1C,Put cell into a hot box. Test condition: Temperature rate :5℃ /min Ending temperature :130℃±2℃ Keep temperature for 30 minutes ,then stop testing and observe 1 h. |

|

6 |

Crush test |

No explosion, no fire |

After the cell is charged with 1C,fixing the cell. Test condition: Direction of extrusion:perpendicular to the pole piece Crushing speed:(5±1)mm/s Crushing plate:A half cylinder with a radius of 75mm,longer than the cell When the voltage reach 0V or eformation get to 30% or extrusion force get to 200kN,stop testing and observe 1 h. |

|

7 |

Seawater immersion test |

No explosion, no fire |

After the cell is charged with 1C,put the cell into seawater or saltwater. Test condition: Concentration:3.5% NaCl After 2 h,stop testing and observe 1 h. |

|

8 |

Temperature cycling test

|

No explosion,no fire,no leakage

|

After the cell is charged with 1C,put the cell into a High-low Temperature Chamber. Test condition: First stage : decrease the temperature from 25℃ to -40℃ Decrease temperature time:60min Holding time:90min Second stage : raise the temperature from -40℃ to 25℃ Raise temperature time:60min Third stage:raise the emperature from 25℃ to 85℃ Raise temperature time:90min Holding time:110min Forth stage : decrease the temperature from 85℃ to 25 Decrease time:70 min Change the temperature from the first stage to the forth stage and cycle five times,then stop testing and observe 1 h. |

|

9 |

Low pressure test |

No explosion,no fire,no leakage

|

After the cell is charged with 1C,put the cell into a Vacuum Chamber. Test condition: Pressure:11.6 kPa Temperature:room temperature Time:6h then stop testing and observe 1 h. |

|

Note: Above testing of safe characteristics must be with protective equipment. |

|||

Huachuang Times adalah perusahaan teknologi baterai canggih di Cina, yang berfokus pada R&D dan produksi di bidang baterai kecil, bersikeras mengambil sains dan teknologi sebagai pelopor, berfokus pada produk dan berfokus pada pelanggan.

Perusahaan telah mendirikan pusat teknologi dan stasiun penelitian ilmiah pasca-doktoral, dan telah mendirikan sejumlah pusat penelitian energi baru bekerja sama dengan universitas-universitas utama nasional dan Institut Akademi Ilmu Pengetahuan Tiongkok. Mekanisme penelitian dan inovasi ilmiah sudah matang dan lengkap. Sebagai perusahaan dengan kekuatan ilmiah dan teknologi yang kuat di bidang baterai di Cina, akan berkomitmen untuk Pengguna menyediakan produk dan layanan daya dengan teknologi dan pengalaman baru.

Hari ini, produk perusahaan telah dijual ke lebih dari 60 negara dan wilayah di lima benua di dunia, sepenuhnya menunjukkan kualitas produk Cina yang sangat baik dan daya tarik perusahaan nasional yang kuat kepada konsumen.

Kategori Produk : Paket Baterai Lithium Ion Polimer > 60 Seri Baterai Lithium-ion Silinder LFP

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.